When assembling household appliances, clinching proves itself by being efficient and reliable. This is also valued by the Swiss premium manufacturer V-ZUG AG, investing in a new system from TOX® PRESSOTECHNIK. It is used for joining the guide plates for dish and cutlery drawers with the side panel of the high-end dishwasher.

The developers of V-ZUG AG know how to bring dishwashers, cooktops and washing machines to the highest quality level. The devices of the Swiss manufacturer are used in private households as well as in the catering sector, showcasing innovative technologies. The start was a lot simpler: In 1913, the galvanising shop Zug AG was established as craft galvanising enterprise, also producing sheet metal goods for households, the agricultural sector and the construction industry. First of all, the business focused on equipment for the laundry room, and seven years into its foundation, launched its first washing machine with drum and manual operation on the market. This was followed by the first small washing machine in 1949. Over the years, washing machines, tumble dryers and dishwashers were added to the portfolio. Since 1981, V-ZUG AG has been trading under its current name. Meanwhile, the former contract manufacturer has developed into a premium supplier and Swiss market leader for household appliances.

One particular feature of the latest development sets new standards with regard to ergonomics: At the start of 2020, V-ZUG introduced the new Adora dishwasher range with the so-called OptiLift. Behind this is an ergonomic function, which swings up the bottom dish rack. This way, dishes etc. can be put in comfortably and removed again later. To be able to support the guide rails and mechanics of this drawer as well as the ergoPlus cutlery drawer, stainless steel sheets had to be fixed inside the dishwasher housing.

The clinch procedure from TOX® PRESSOTECHNIK GmbH & Co. KG is ideal for this purpose: It joins the thin stainless steel sheets reliably and quickly. Compared to riveting or welding, the surface and material structure remain intact, and thus sealed. “It is the most efficient solution for us”, says Patrick Bon, Head of Dishwasher Construction at V-ZUG. “Whilst we have been using the TOX®-Clinching tools for some years, we have so far never had a complete system from TOX® PRESSOTECHNIK”, he adds.

The concrete task was: Three components each must be attached to the two housing sides of the large capacity tubs. “Our customers expect top quality. For us, this makes it clear that the result must be faultless visually as well as technically here as well”, says Patrick Bon.

Dynamic and accurate

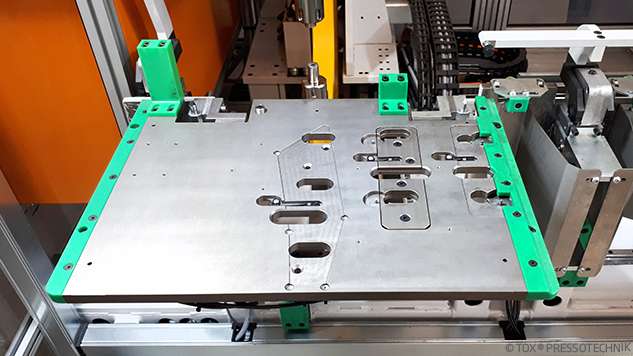

TOX® PRESSOTECHNIK developed a system concept which enables clinching of two housing panels in one process. The TOX®-Single-Point Tong TE-CM with their electromechanical drive TOX®-ElectricDrive in compact design form the core for this. The C-frame is designed for a maximum press force of 80 kilonewton. The tool opening is a maximum of 73 mm and is thus completely sufficient for the Swiss project. The EPMR press drive is installed on die side and works with a nominal force of 80 kilonewton. Sensors monitor the force and distance path. The accuracy of the highly precise force sensor is ± 1.0 percent of the measuring range end value. The piston of the drive works highly dynamically with a speed of up to 200 millimetres per second. Before each setting of a clinch point, the component surface is lubricated. This reduces friction, thus preserving the tools and sheet surfaces. TOX® PRESSOTECHNIK has added a spraying system to the system for this purpose.

Once the three sheet metals have been placed on the work table – a mixup and faulty installation is impossible due to the template-type component holders – the operator then places down the 60 litre large capacity tubs. He uses the TOX®-Single-Hand Control STE to release the travel-regulated process. The housings are fixed, and the clinching process is started. The tongs move on a X-Y-axis, to machine two side panels one after the other with 15 TOX®-Joints each.

Variable process

There are two programs: One for clinching three and one for clinching two sheet metals per side. “This way, we can produce the housings for dishwashers with and without Comfort Slide function for the cutlery drawer on one system”, says Christoph Fässler, Project Manager for system planning. As soon as the process is complete, the control opens the component clamps automatically. The operator then removes the housing, reloads the work table and places the tub, which is rotated by 180 degrees, down again, to repeat the process on the second side panel. The user can use a touchscreen for creating motion sequences and operating mode, and to view evaluation results. The screen is connected to the axis controller via an Ethernet connection.

To avoid errors or even injuries, TOX® PRESSOTECHNIK has equipped the system with several safety features. Sensors check whether the required components were inserted and the tub was placed down. The system is only accessible from the front, whereby light curtains monitor access during the process. The other sides are sealed off via macrolon panels. This way, operators can safely keep an eye on the joining process.

V-ZUG uses a flexible approach. For example, the control can later be used for additional tub versions. By the same token, all component holders are designed as interchange parts, allowing retrofitting at a later stage.

V-ZUG received the system at its site in Zug ready to use and it only had to be connected to power and compressed air. “Everything went very smoothly”, says Christoph Fässler looking back.

“For us, it is not about maximizing output, but about quality, which impresses technically as well as visually with TOX® PRESSOTECHNIK.”