Option for all TZ-Tongs: indexing slide with stroke adjustment and pneumatic cylinder. Large stroke to clear the TOX®-Button or any embossment on the parts. Includes end position sensor.

Robot & Machine Tongs

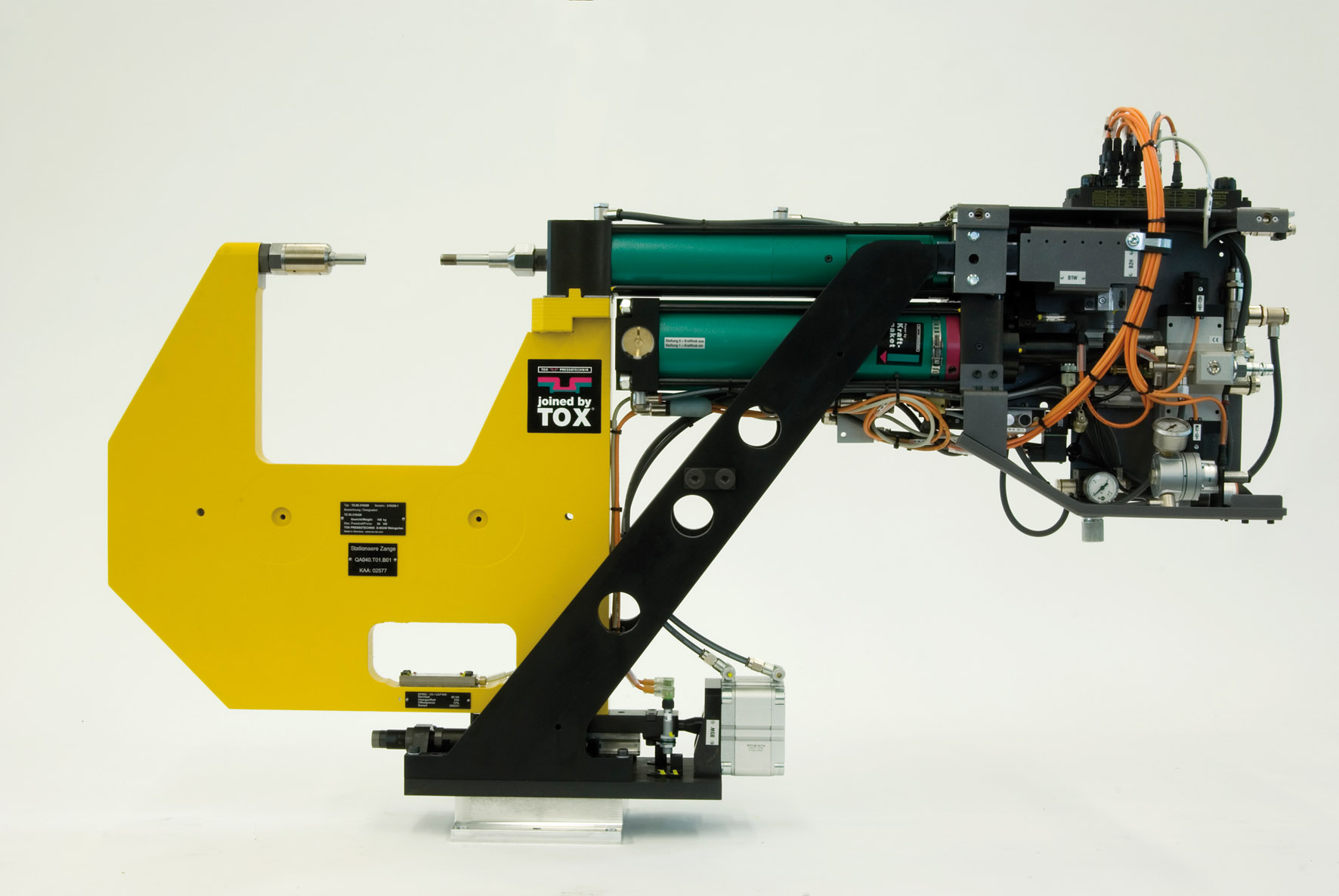

Busy in fabrication: Robotic & Machine Mount Units

The modular concept for handheld-, machine- and robotic press units provides an ample freedom to match these TOX®-Units to the used parts and handling equipment.

TOX® PRESSOTECHNIK provides solutions to all application and quality assurance requirements with a clearly defined interface.

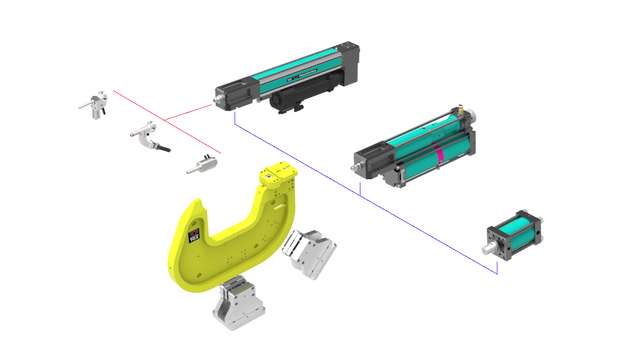

Components of the TOX®-Robot Tongs modular kit system:

The precise adapter flange on the TOX®-Drives type RZ provide an exact alignment of the drive.

There are pneumohydraulic and hydraulic drives als well as electromechanical drives available.

The tooling of the TOX®-Robot Tongs depends on the used application. The toolset consisting of punch and die can also be mounted for die side drive.

Special strippers and equipment for robot tongs are standarized as well.

Depending upon your project-specific needs, we provide different accessories and additional equipment within our modular kit system.

Option for all TZ-Tongs: indexing slide with stroke adjustment and pneumatic cylinder. Large stroke to clear the TOX®-Button or any embossment on the parts. Includes end position sensor.

Option for all TZ-Tongs: drive with die indexing slide.

Applicable to units with the die mounted on the drive side. It prevents any undesirable loads on the workpiece.

Special Punch stripper with thread for drives RZK, RZH, EPMR.

|

Contact

IN: +91 20 66538300

Contact form

|

|

Cookie Information

We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |